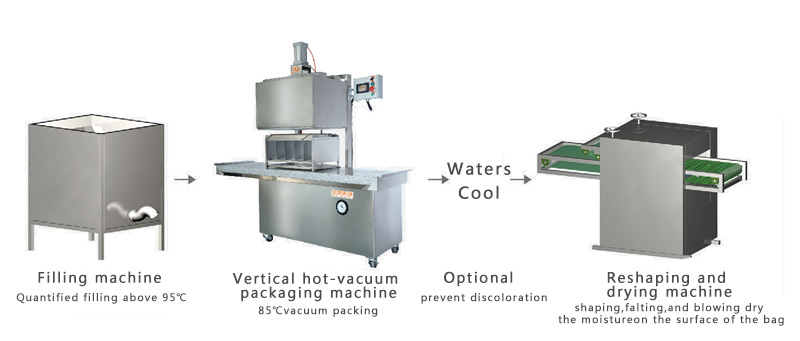

Applications:

Viscous materials: bean paste, lotus seed paste, fruit stuffings, meat, chili sauce, pickles, etc.

Cereal products: sugar natto, brick-shape-bagged beans, rice, etc.

Industrial or pharmaceutical products: electronic substrates, industrial parts, medicines, etc.

Features:

Equipped with advanced automatic control system to realize double vacuum operations.

Text-display screen design. Easy to use.

Self-inspection design available to provide real-time monitoring for temperature control system, vacuum system, and in any abnormal heating situation.

Able to vacuum and seal products with product temperature above 85°C, depending on package type and unit weight.

Vertical sealing maximizes the use of vacuum chamber space. A maximum of 48 packages can be packed each time.

Heat sealing temperature adjustable ranging from 0-199℃ to ensure sealing quality.

Sealing pressure adjustable ranging from 0.4-0.6Mpa/cm2 to ensure sealing strength.